Creating branded promotional basketballs is a great way to create new truenesses with your customers and enlist them to spread your brand to new audiences. But you will have to do it in a way that makes viral sensations, not just round shaped pieces of rubber that will never leave the garage. Here is how your promotional basketball will be made... on that note, check out how your promotional surfboard was made from here

Preparing the 'underwear' of promotional basketballs

The process of making a promotional basketball starts with the interior bladder. Butyl rubber is melted in bulk inside a hopper and fed through a press that turns into a continuous sheet 12 inch and 0.5 inch thick. A guillotine shaped cutter then cuts the strip into small sheets that are 18 inches long. The sheets are stacked up against each other in order for a hand controlled robot to select the 18 inch sheet one after the other.

A punch press is used to make a one inch diameter hole that will be used to feed the air tube that will be used to inflate the bladder. The sheets are transported on an elevator to an assembly line where workers insert an air tube through the hole that was made.

The shaping of the bladder is made using a heated cast device that bonds to the sheet (folded into quarters). This is then fed through a second punch which punches out rounded edges and at the same instance binds the edges to create the seams of the bladder.

The bladder of a promotional basketball ready to receive the carcasses

Since the bladder is not well shaped, it is taken to another machine where the rubber is heated under very high pressure making it more flexible, durable and stronger. The bladder is now ready to be inflated. For the bladder to pass quality control, it must at least hold air for 24hrs else it will be recycled. Assuming the bladders passed the quality control tests, they are transported to the winding area. Here, machines wrap several strands around each bladder. The thread depends on the spool fed to the machine and it might be either polyester or nylon. This process gives the irregular bladders a more rounded shape.

How the bladder of a promotional basketball appears after winding process

How the bladder of a promotional basketball appears after winding process

The difference between your normal promotional basketball and the NBA basket ball

The type of thread and the number of strands determines the quality and cost of the ball being made. For example, the typical basketball you will find people playing in the street will most likely have three strands of polyester while the branded basketballs used by professional teams will have nylon thread and about four stands of thread.

The carcass is now ready to meet the cover.

As the bladders were meeting the carcasses, another part of the factory was preparing the covers. The covers are made from rubber that comes in continuous rolls. The rubber is typically smooth with no bumps like you would find in the real ball. A typical promotional basketball needs six panels. The six panels are cut out from the continuous rubber roll. One of the panels will have a hole that will cover the air tube. The six panels are picked and carried to a vulcanizing machine. The bladder and carcass are now covered with a special glue and placed in the vulcanizing machine. The vulcanizing machine will press the six panels into the carcass/bladder and add any embossed information required. At this moment, the surface is still smooth without any pebbling. The promotional basketballs are inspected and those with air gaps filled. They are then subjected to another vulcanizing process where they get the pebbling.

Customizing and branding basketballs.

Custom basketballs make excellent gift items not to mention an excellent way to push a brand or message and other promotional activities. There are several different ways to customize a promotional basketball. Your brand, or logo can either be printed on the surface of the basketball using either A/B paper or a special UV printer.

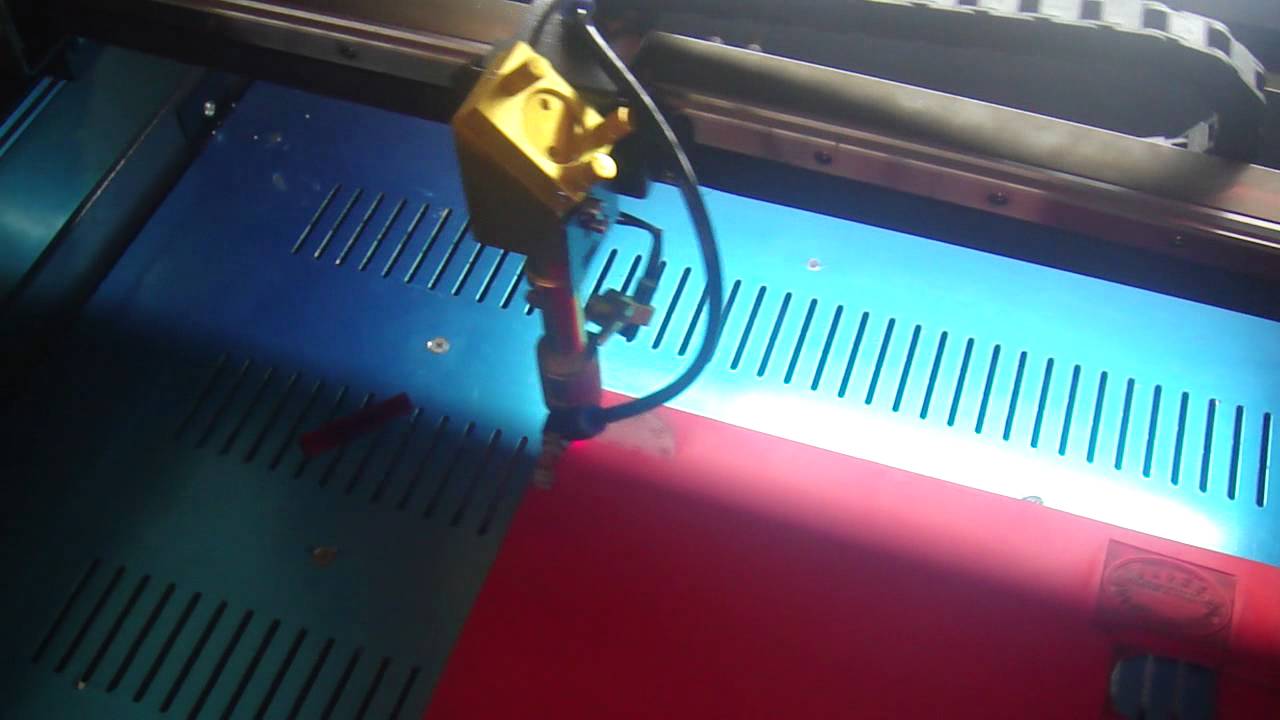

Laser engraving a rubber similar to the one used in promotional basketballs

Laser engraving a rubber similar to the one used in promotional basketballs

Alternatively, you can have laser engraved logo or design of your choice on your custom, promotional basketball. For high quantity orders, you can get a completely custom panel colors with your design all over the promotional basketballs. Whether you are looking for tournament play balls, giveaways, or fundraising promotional basketballs, DisruptSports can help you find and create the perfect option for your needs.